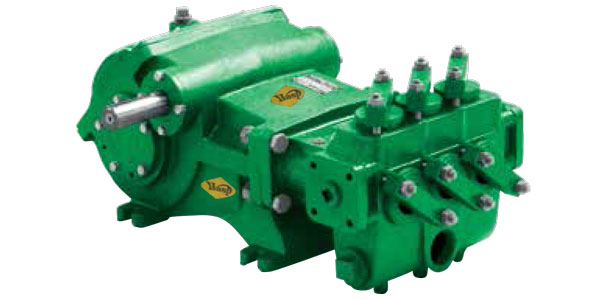

High Pressure Reciprocating Pumps (D40, D50, D55, D60, D65)

(106 lpm to 400 lpm) (34 bar to 152 bar)

The D Series combines WASP manufacturing expertise and understanding of applications to provide a pump that is perfect for every high pressure job. At WASP we know your need and we deliver.

A high strenght fluid end with spring loaded flat valves for pumping large volumes of water under high pressures 152 Bar. Handles liquids up to 180 F in minses, food process-ing, and car/truck washes.

This is a high-volume, high-pressure pistion Pump. Can’t be beat for hydraulic blasting and cleaning , sewer cleaning, fire truck, injection, able service in many exacting industrial high pressure applications.

This pump’s large 400 LPM volume of flow at up to 152 Bar makes it perfect for sewer blasting as well as extra heavy duty industrial and marine cleaning. The compact, powerful design is also right for strata loosening, long distance pump vehicle cleaning. This is a high-volume, high-pressure pistion Pump. Can’t be beat for hydraulic blasting and cleaning, sewer in many exacting industrial high pressure applications.

FLUID-END COMPONENTS

- Cylinder body of high-strength ductile iron or aluminum-bronze for salt water application.

- Cylinders are tapered steel shells with (optional) super-smooth hard K-ramic coating. Easily replaceable.

- Packing : Buna-N & cotton duck multi-lip V-ring supported by a phenolic follower.

- Piston assembly : Stud, pressure rng, spring, retainer and cap screw are all solid stainless steel.

- Valve assemblies are spring-loaded flat valves having stainless steel seats, springs and valves with long wearing stainless steel retainer. Stainless steel center post type feature delrin valves.

- Valve and Cylinder caps of tough cast iron with Buna N O-ring seals. Caps are rigidly held in place removable steel clamps.

- Suction & discharge located for easy service. Large threaded suction opening on sides and/or front. discharge openings are flanged and tapped.

POWER-END COMPONENTS

- Gearcase of rugged cast iron protects the gears and serves as oil reservoir for continuous lubrication. Cover section quickly removable for easy service.

- Pinion & main gear are helical cut and machined from high-strength alloy steel, and rotate in either direction. Integral pinion shaft is also machined from high-strength alloy steel.

- Automative type crankshaft is of high strength ductile iron.

- Shaft bearings feature tapered roller bearings.

- Crankshaft journal bearings are automotive Type, steel-backed inserts.

- Connecting links are ductile iron with replaceable bronze wrist-pin bearings. Wrist pins are press fitted into the crossheads.

- Crossheads/piston “pony” rods: Heavy – duty ductile iron crossheads “pony” rods are smoothly-ground and highly-polished stainless steel, threaded and pinned axially to crosshead.

- Continuous splash lubrication is provided during either direction of rotation.